Food-Grade

Aluminum

For the production of our pans & pots, only food-grade aluminum is used, which is heat-conductive, lightweight, anti-corrosive and non-reactive to food.

For the production of our pans & pots, only food-grade aluminum is used, which is heat-conductive, lightweight, anti-corrosive and non-reactive to food.

Nonstick coatings from our reliable suppliers are PFOA-free. High wear & temperature resistance ensures both cooking safety & durability.

Made with bakelite which is non-conductive & highly

heat-resistant, handles of our pans and pots will stay cool for easy holding & serving.

When it comes to the quality of our cookware, we don't believe in shortcuts.

Every pan and pot will go through at least 8 meticulous processing steps before it becomes GPR Cookware.

The surface of each aluminum pan or pot is carefully inspected before & after molding to ensure there's no bubble or scratch.

A caliper & dilatometer are used to check if the cookware dimensions, rim thickness & bottom concavity meet the designated requirements.

After covering the bottom, our worker will strike the bottom of every pan or pot with a small copper hammer to make sure it adheres firmly.

Then the magnet is used to check the induction performance of every pan and pot by our bottom-covering worker.

Coating testing machine & 3M 898 adhesive tapes are used to check the thickness, hardness & adhesion of nonstick coating every 1 hour.

Every part including the handle & the lid is carefully tested & inspected after assembly. No scratch, grease or unsightly welding spot is allowed.

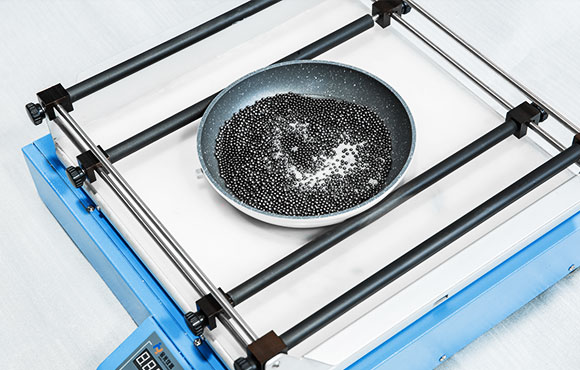

Anti-abrasion performance of the non-stick coating is tested with 3M 7447 scouring pads which is attached to a testing machine that wipes for 3000 - 5000 cycles.

Bottom concavity should be within a low value in 10 repeated tests. We measure the value with a dilatometer when the cookware is cooled down from 200℃ to 20℃ after a thermal shock.

To test the heat-resistant performance of the non-stick coating, we put the pan or pot into the thermotank and heat to 250℃.

Anti-corrosive performance of the non-stick coating is tested with 5% NaCl. The solution is heated for 7 hours.

We put the pan or pot into the dishwasher for 50 washes (45 minutes each time) to ensure it's dishwasher-safe.